For peak performance, service the entire system instead of simply installing new boxes.

Pity homeowners who are seeking to replace their existing heating or cooling equipment. As an industry, we’ve done a good job promoting high-efficiency equipment, but we haven’t done enough to ensure that the new system actually performs as advertised.

Yeah — it likely blows warm or cool air and it most likely will perform better than the one it has just replaced. The homeowner may even have engaged a utility program that offered a rebate for buying an Energy Star-qualified system.

Our homeowners will hope that the $8,000+ they spent on an HVACR system will reduce their energy bill. But — to be honest — technicians are often too busy to check the performance of the system, even if they know how. And the homeowner will be stuck with poor comfort, ongoing maintenance and high utility bills. It’s just not fair and it’s not necessary.

The Industry Reality

Sadly, when we do follow-up evaluations of HVACR systems, we find that they seldom perform at their rated capacity, with bad consequences for energy consumption, comfort, safety and maintenance.

These systematic shortcomings are caused by many factors — one of the biggest being the homeowner who does not understand or demand proof that the new system is performing as well as the slick brochures claim. Ignorance is bliss — until things such as oversizing, short-cycling, duct leakage and high static pressures undermine the system’s proper operation.

I hate to simplify this as “It’s the installation, stupid,” so let me be more clear. It’s the design, the ducts, the commissioning and the maintenance. All of these must be verified to ensure that the system performs as the manufacturer intended, the contractor hoped and the homeowner expected.

The situation is often not much better on jobs that are implemented by home performance contractors who are focused primarily on the building envelope.

Many of these firms do not have the expertise, tools or licensing that would enable them to address problems with the HVACR system effectively. So the HVACR work is subbed out — and the home performance contractor cannot ensure that the homeowner got a high-quality HVACR installation.

Why This Happens

Unfortunately, many HVACR installations are implemented as rush jobs. Part of the problem is that price pressure and competition are severe in today’s market, whether the HVACR contractor is working as a subcontractor to a general contractor or directly with the homeowner.

Homeowners seldom maintain their equipment and when a minor problem crops up, they often choose to fix and forget until the system fails catastrophically. Then comes panic time and another rush job. Most homeowners consider HVACR equipment to be a simple piece of plug-and-play machinery and they have no idea how complex it is to design and commission a new system. Nor do most HVACR contractors have time to educate them.

Adding to this crisis planning is the fact that HVACR systems do not usually fail in good weather, so the working conditions around HVACR replacement are often trying: It’s either 95F in summer or 20F in winter. At times like these, many systems are often failing within the same community and the good contractors are overbooked.

If a homeowner is lucky enough to get a reputable and quality-minded firm to bid on the job, that firm’s higher price — which is justified by its better workmanship — will likely push the homeowner to get multiple bids.

Given this situation, it seems like an easy choice for most homeowners to find a contractor who can install a new box tomorrow for thousands of dollars less than the competition.

But will this low-bid, Chuck-in-a-Truck follow the manufacturer’s installation guidelines — or industry specs such as the ACCA Quality Installation Standard — on sizing, equipment selection, duct design and airflow and charge? Not likely.

And so the cycle repeats itself: little if any design, little oversight of commissioning, little regard for maintenance and little attention paid to ducts. For the next eight to 10 years, at best, the homeowner is stuck with an underperforming HVACR system.

The ESVI Solution

My colleagues and others working with us at the U.S. EPA hope the Energy Star Verified HVACR Installation (ESVI) program will solve this problem. Launched last year, ESVI helps bridge the gap between the designed performance and the installed performance of HVACR systems.

By verifying the quality of installations, contractors will ensure that homeowners receive the value for which they’ve paid, competent contractors will gain market advantage for the good work they already perform and sponsoring utilities will have verification that energy savings are realized.

|

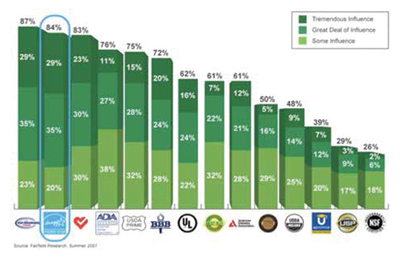

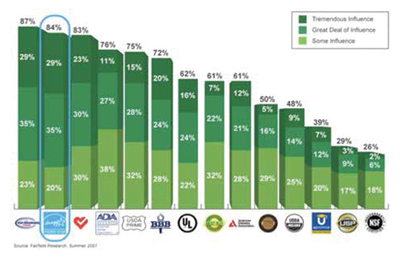

Fig. 1 — Energy Star is one of the most recognized trademarks in the world (Fairfield Research, Summer 2007).

|

The ESVI program, with its emphasis on remote reporting of system performance, benefits from the advent of “Smart Systems” that offer real-time guidance for system installation, commissioning and operation. These systems allow all parties to verify that the original equipment manufacturer’s (OEM’s) key performance metrics are achieved and reduce the need for expensive third-party verification visits.

The ESVI program allows EPA to extend the respected name of Energy Star to HVACR systems that have been verified to perform as advertised (see Fig. 1).

With the help of progressive utilities and HVACR contractors, we’ll bring the message “It’s all in the installation” to the consumer market.

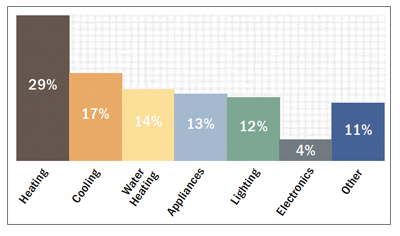

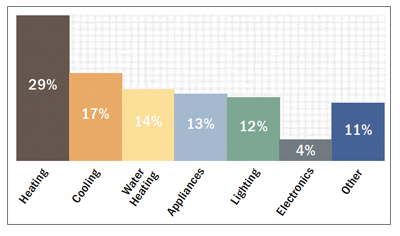

Verified HVACR installation is the last substantial low-hanging fruit on the savings-and-comfort tree and we’re bringing it within reach of the industry (see Fig. 2).

|

Fig. 2 —You cannot ignore the HVACR system in well-crafted, whole-house retrofits — it can account for much of the energy consumption in most climates (EPA).

|

The ESVI program is being implemented in cooperation with existing utility-sponsored demand-side management programs, in a similar way to the Home Performance with Energy Star program for existing homes and the Energy Star Certified Homes program for new homes.

And while the technical specifications of verified ESVI installations will remain consistent and supportive of Air Conditioning Contractors of America (ACCA) standards, local program implementers will be allowed the leeway to apply the standards in ways that are compatible with their existing programs and policies and which give them Energy Star marketplace advantage.

Why ESVI Is a Good Idea

Homeowners gain peace of mind, comfort and safety when their system fits the house and performs properly. Their home gains value.

With ESVI in place, utilities will have verification that the performance and savings of HVACR systems are real.

Quality-Minded Contractors can now participate in a program that rewards high-quality installations and provides strong market differentiation for their superior work.

Any improvement in energy efficiency results in a whole slew of external benefits. Verifying the quality of your work in a transparent process is a good idea for everyone.

Future of Verified Installation

Homeowners who have comfort problems often call an HVACR contractor. The HVACR industry holds the keys to a large number of households — HVACR technicians are ringing more than 100,000 doorbells a day across America, far more than our home performance contractors.

We see a logical partnership between these industries. Home performance remediation is the comfort key that the HVACR industry struggles to capture and high-quality HVACR work is often missing from home performance jobs that focus on the building envelope.

There is a lot of opportunity here, though the road to success is crowded with barriers. But having a way to truly verify the operation of HVACR installations will overcome many of those barriers.

Imagine installing an HVACR system that you know will deliver what was promised. Imagine the value added to high-quality jobs performed by contractors who do the best work. Imagine if homeowners could have ongoing confidence that their system’s performance will be monitored and tuned up over the years.

It all starts with a verified quality installation, with baseline performance measurements that can be used over the lifetime of the equipment and an agreed-upon set of industry standards to guide the process.

Chandler von Schrader has worked in the energy efficiency industry since 1981, selling and installing solar DHW systems, performing residential energy audits, delivering demand-side management services and providing sales and marketing support for the HVACR industry. Chandler now leads the Energy Star Verified HVACR Installation program. For additional information, visit homeenergy.org.