Most business owners understand the high cost associated with heating and cooling their facilities and therefore frequently look for means to reduce these costs. According to various research studies, commercial building owners pay an average of $6.79 per square foot in non-fixed operating expenses, with over half of the budget going toward HVACR costs. However, these costs come in many forms, not just the apparent more impactful frontrunners. The insidious additional financial impact over time can add up.

They include in part, these factors:

- The impact of downtime when HVACR equipment is not running

- Facilities incurring time and labor lost maintaining equipment or responding to building occupant comfort complaints

- Undertaking the responsibility of sustainability issues and/or addressing excessive carbon emissions when there is an ever-present opportunity for reduction

Efficiency Loss: The Costs & Tracing it Back to Maintenance

When operational efficiency declines, the result is greater energy consumption, carbon emissions, and increased utility costs. There can be a variety of factors associated with efficiency loss as well as the associated rising costs. And, while some of these cause-and-effect conclusions are obvious, others often go completely unnoticed, and it affects the business’s bottom line. As equipment ages, associated operational costs go up, requiring more time for maintenance. Each of these fractional costs can ultimately lead to a greater financial impact. However, each respective department may feel the financial effects of HVACR equipment differently.

Given that HVACR equipment has a relatively long-life expectancy, it is quite common that if one is in business long enough, the facility will experience multiple operational use changes. Namely, internal loads, for instance, change with added and reduced occupant headcount, including changes to working shifts and new heat-generating equipment. Since HVACR systems are rarely rebalanced for every significant change in an organization, the upkeep or lack of upkeep is a common issue businesses face, and one that ultimately can result in less efficient system operations. So, a less obvious source of efficiency loss is the continual degradation of the operating performance of the HVACR equipment. In other words, the performance loss accrues slowly, over time.

Oil Breakdown, Contamination & Degradation

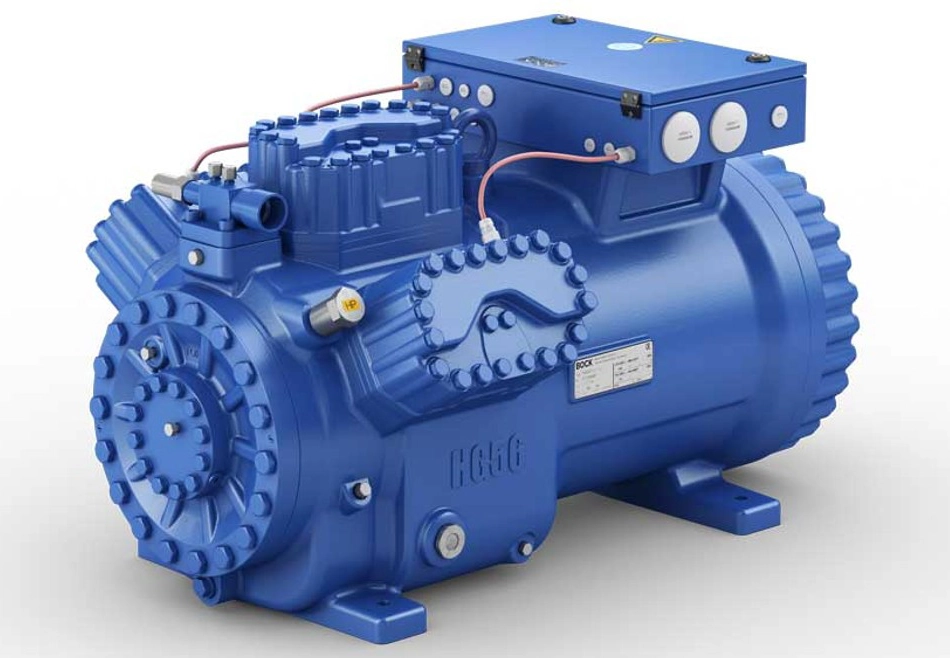

HVACR performance is principally affected by two attributes: 1. mechanical friction, and 2. heat transfer. Most mechanical systems rely upon oil to reduce friction effects and are susceptible to oil degradation over the life of the equipment. Eventually, oil contamination and oil breakdown can result in compressor degradation or failure. With the advent of oil-less magnetic bearing type chiller compressors, the oil concern may be eliminated eventually. However, currently most chiller systems - and all DX systems in service today - utilize oil.

Providing sound maintenance programs on systems with accessible compressor crankcases or oil sumps allows the opportunity to monitor and replace degrading oil. Although many systems have hermetically sealed compressors making oil changes much more labor-intensive and costly and, in some cases, regular monitoring service often gets skipped. But not only does regular maintenance allow the opportunity to create more energy efficiency, but also allows HVACR companies the opportunity to leverage consumers’ economic, sustainability, and energy concerns. should be scheduled in advance.

Note: While advancements in refrigerant oil types have greatly helped the longevity of oils, even synthetic oils wear over time.

Oil Buildup or Oil Fouling, The Cost & The Solution

Compressors, Refrigerants & Oil 101

1. The compressor process - In addition to reducing frictional forces, compressor oil serves another important function: sealing the gaps between moving parts. A compressor’s function, as the name implies, is to compress the vapor state of the refrigerant. The refrigerant, under pressure, tends to squeeze through gaps between mechanical parts. Refrigerant seepage into the oil crankcase is limited by the wetting surface tension of the oil between the moving parts. Inevitably, some oil within the compressor mixes with the refrigerant and works its way into the refrigerant loop. As the refrigerant flows through the system, it carries and deposits the oil throughout the heat exchanger coils.

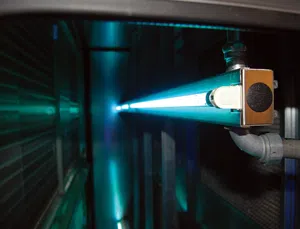

2. The resulting oil buildup - Over time, oil buildup becomes significant enough to reduce efficient heat transfer between the refrigerant and the heat exchanger coil surface. HVACR engineers have designed systems to allow for some oil to circulate with the refrigerant, incorporating a way to return this displaced oil to the compressor crankcase or sump, where it belongs. Yet the oil that remains on the surface of the heat exchanger coils, reduces the overall system efficiency. Oil buildup is more prevalent in the evaporator coil but also occurs in the condenser coil. Oil migration is largely impacted by the refrigerant flow velocity, with significantly higher velocity in the smaller diameter high-pressure lines. Once the refrigerant passes through the expansion valve, the velocity drops, causing a drop in temperature and making it easier for the migrating oil to deposit on the evaporator coil walls.

This process causes a slow oil migration and leads to oil buildup, also referred to as oil-fouling, (not to be confused with oil-logged evaporators). Oil-fouling creates excessive work for compressors in delivering called-for BTUs and can lead to increased energy use and shortened system or component life. The supply chain issues faced today with HVACR replacement systems and components are taking much longer to procure than ever before. Additionally, inflated prices have us all in need of extending our current equipment longevity while looking for methods to reduce operational costs. Also, the need for added equipment and service calls increases the potential for refrigerant loss, and negatively affects businesses’ BPA compliance.

Combating Oil-Fouling – Simple Solutions

While oil-logged evaporators have a litany of potential fixes, including extensive equipment teardown and reassembly, as in the need for a compressor heater or other corrective measures, oil-fouling can be remedied with a much simpler solution.

The Advancement of Oil Fouling – A Simple but Overlooked Solution

Early stages in oil-fouling treatments, gave the entire process a bad rap. Treatments for oil fouling were first developed decades ago with mixed outcomes. Early treatment formulations chemically cleaned the oil from the heat exchanger coil surface, which resulted in breaking down the oil. This solution was detrimental to lubricating properties and inevitably shortened the life of compressors. Other early treatment formulations included solid particles intended to enhance heat transfer from the refrigerant to the heat exchanger coils and to improve the lubricity of the compressor components. Components that once deposited, negatively changed the function of the expansion valve. This too wasn’t the best solution.

Today, advances in material science have enabled oil-fouling treatment solutions to finally perform as intended by displacing deposited oil from heat exchanger coil walls and putting the oil back into circulation with the refrigerant. Various methods or physics explanations have been used to describe how the oil is being displaced without the use of solvents or other cleaning chemicals, but most seem to rely on an attractive force stronger than the wetting bond of oil to the coil surface. Some have described it as a covalent bond, others, as a weaker Van der Waals force. Additionally, some oil-fouling treatments also claim the benefit of improved lubricity of the compressor components, an easy claim to make with the advent of synthetic refrigerant oils. Suffice it to say, the advances are game-changing.

Although the science is here, oil-fouling treatment solutions still face market resistance due to several issues.

These concerns include:

1. The legacy of poorly performing oil-fouling products precedes the latest advances causing consumer resistance

2. Some solutions offered are not supported by professional data analysis consistent with International Performance and Verification Protocol (IPMVP) data collection and analysis methods, leaving potential clients questioning the soundness of the product itself

3. The difficulty in demonstrating performance gains with available clients’ utility data is leaving consumers weary. For example, a typical building may apply 40% of utility energy for HVACR and with oil-fouling treatment achieve a 10% - 15% HVAC energy efficiency gain, resulting in an overall 4% - 6% utility energy reduction. This can be very difficult to demonstrate and trace back to oil-fouling treatment, especially with highly variable month-to-month utility data

In full discretion, I am biased, in that I work with ThermaClearTM. However, I can still speak to the science, and advanced technology. The advanced qualification methods as well as overwhelming data points to rigorous compatibility testing and the extensive IPMVP methods to quantify restored efficiency performance. Like most, I was largely unaware of oil fouling but have found a great appreciation for this lesser-known cause of HVACR efficiency loss. Knowledge is power - so we can gain back lost HVACR performance and contribute to reduced energy consumption, lower utility costs, and the enviable position of furthering decarbonization at an affordable price. While the sustainability community is eager to implement more sustainable energy sources, we need not forget the additive benefit of first reducing current energy uses and lessening the burden on future sustainable sources. Now is an excellent time to look at simple ways our HVACR systems and the industry as a whole, can contribute to long-term decarbonization goals.

Michael Daly, P.E., Chief Technology Officer at ECM Technologies, is a seasoned professional with 30-plus years of engineering and business management experience. He has made a career in developing, manufacturing, and selling lifesaving and life-changing technologies focused on energy conservation measures. Michael has a PE license in the State of Arizona, with his BSME from the University of Arizona, and executive education through the Harvard Business School Program for Management Development. Additionally, he received his program management certification, PMP through PMI and is certified in several quality methodologies