This discussion is about vibration isolation – and how a few simple steps taken with rooftop and other above-grade installations in commercial or multi-unit residential settings can save you from a lot of grief and damage to your reputation.

All rotating and reciprocating equipment produces vibration - determined by the speed and amount of unbalanced forces present. Usually, the more expensive or better maintained the HVACR moving parts, the less vibration will be produced – but even a small amount of vibration transmitted into a building can cause severe problems.

With installations on grade, vibration is usually transmitted into the ground where it dissipates. Above grade, it becomes essential that any vibration be isolated from an occupied structure, lest it be transmitted through it (sometimes at significant distance) to excite floors, wall and ceilings and produce audible (or even sub-audible) noise – and complaints. The greater the vibration, and the lighter the structural elements, the more critical the issue becomes.

Vibration that cannot be eliminated at the source must be isolated. This is accomplished by mounting the equipment on isolators, typically made of rubber, springs or pads. Isolators are selected based upon the following criteria:

The sensitivity of the structure and environment to the vibration

The speed of the equipment.

The amount of vibration present at the mounting point, which determines the amplitude.

The weight (and weight distribution) of the equipment.

Durability factors

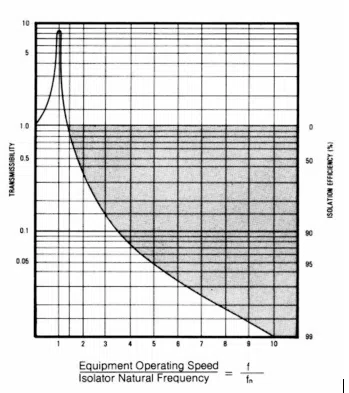

The lowest speed of the equipment generally determines the forcing frequency of the vibration. This, and the amplitude of the vibration, is critical in specifying the type of isolator to be used, and its natural frequency. As shown in the illustration below, no isolation exists unless the ratio of the forcing frequency of the source to the natural frequency of the isolators exceeds 1:1.4. The isolation efficiency increases as this ratio increases. It is important to note in this illustration that the selection of the wrong isolator, where the ratio is below 1:1.4, will result in an amplification of the vibration of up to ten times. We have even seen this happen in Miami rooftop installations where rubber mounts, initially providing only marginal vibration isolation, have hardened with age and heat exposure to provide less deflection and negative isolation, resulting in increase vibration and noise transmission to high-priced residential units.

All isolators are rated by their operating weight range and deflection. Pads less than 1” thick are usually appropriate only for on or below-grade installations. For less critical applications, or when the forcing frequency is relatively high (such as high speed motor or pump), rubber-in-shear mounts, as shown below, may suffice, but these are usually reserved for interior use.

For more critical applications, particularly when the forcing frequency is low, spring mounts having a full-load deflection of 1” or greater should be selected. Isolation efficiency increases with isolator deflection and resultant lower natural frequency. We do a lot of work with a company that produces pulse-boilers. Even though the source frequency of the vibration is relatively high, they opt to isolate their boilers in above-grade installations using spring mounts.

With large pieces of equipment, where high deflection isolators are being utilized, an inertia base may be used. This virtually eliminates the transmission of much of the vibration, and lowers the center-of-gravity of the installation to provide more stability. The downside is that an inertia base may add weight to the installation that is structurally unacceptable.

Special restrained element isolators may be selected to protect equipment against severe wind-load or seismic activity. Examples of such isolators are shown below:

But vibration isolation doesn’t stop with the equipment alone, as it may be transmitted through piping and conduits. Flexible connections help reduce direct transmission to piping, but fluids may transmit equipment vibration as well, and fluid flow may induce additional vibration into the piping that can be transferred to the structure. We ran into this type of problem with a 5th floor luxury condominium in south Florida where pipes running from a pump in the basement to the rooftop chiller transmitted pump and fluid flow vibration into the walls of a residential unit simply because the piping had been firmly attached to the metal wall studs.

Piping isolation hangers, as shown below, are an extension of the equipment isolation. The piping must also be isolated when touching vertical surfaces or passing through floor or wall penetrations, using resilient wrap or caulking.

It pays to do it right the first time. Don’t hesitate to seek advice from a competent professional – or simply give us a call at 888-667-3723.

Robert N. Andres, Sr. is the founder of Oshex Associates, Inc. (800-LESS-LOUD), product distributor and specialists in industrial, community and building noise and vibration measurement and control since 1975. He is a Certified Safety Professional, Certified Plant Engineer, Board Certified Forensic Examiner, a member of the Institute of Noise Control Engineering, and principal of Environmental and Safety Associates, LLC, of Naples, FL and Syracuse, NY, specializing in noise and vibration control and machine safety engineering. He may be reached at esaconsulting@comcast.net.